HYBRID MANUFACTURING: THE ADVANTAGES OF AN ADDITIVE/SUBTRACTIVE PROCESS

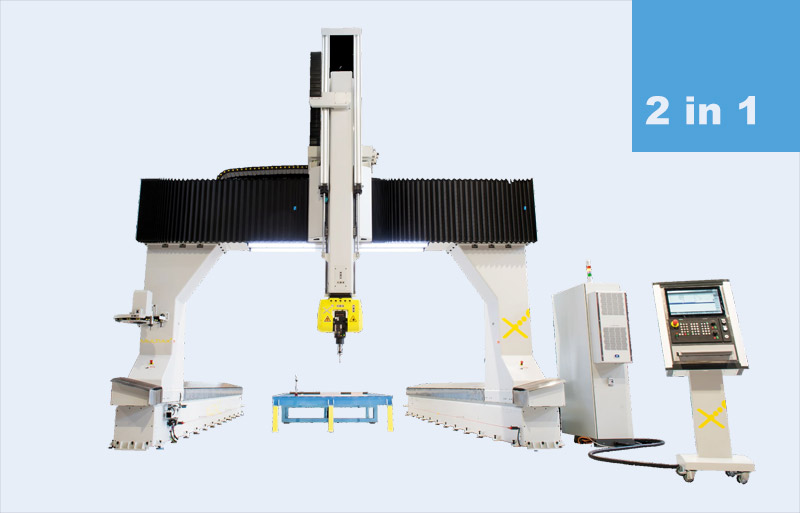

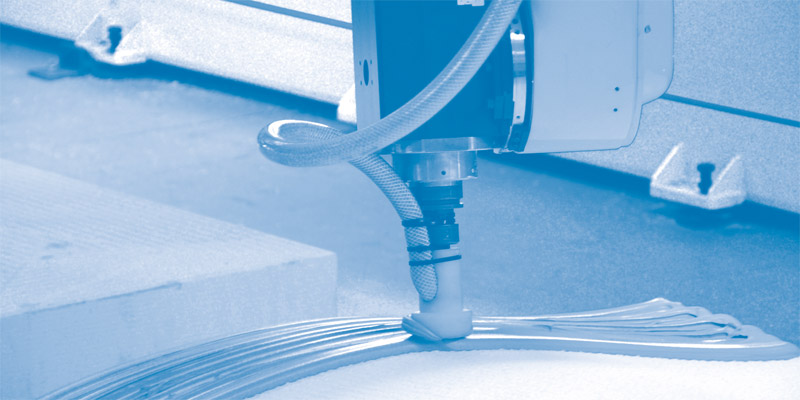

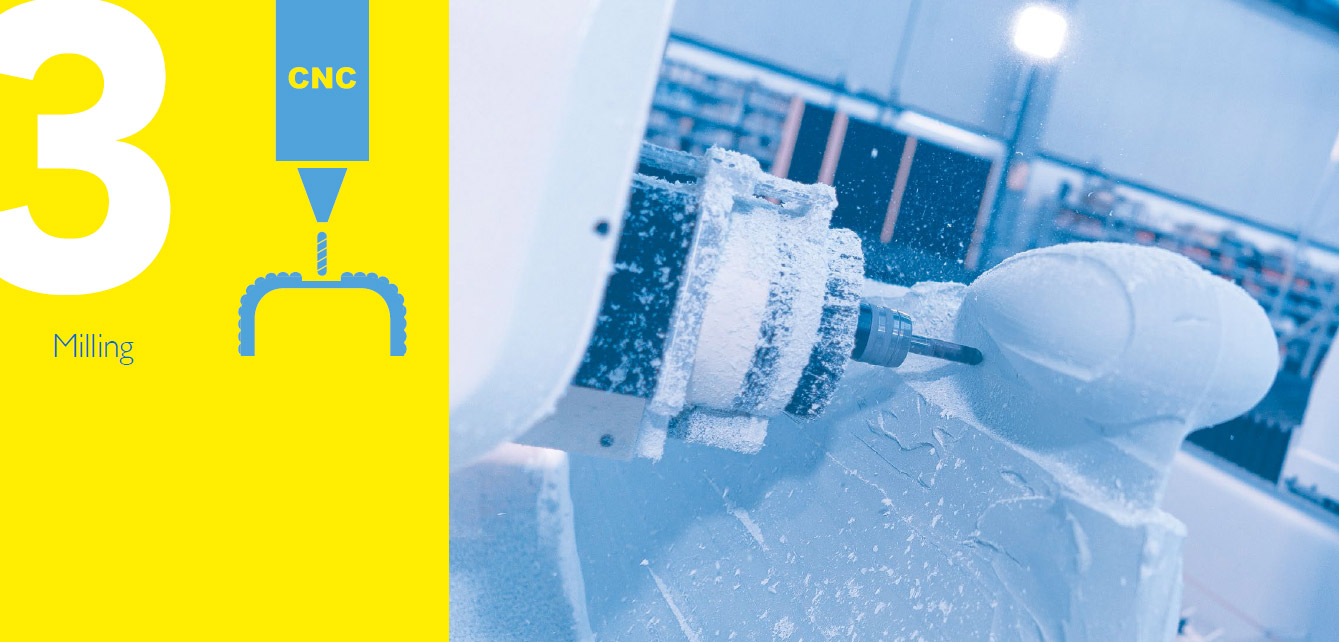

Integrated process of Modelling Paste Extrusion and Milling with the same CNC Machine

As the industry trend is toward larger parts, the key challenge is to find ways to produce parts at lower cost and reduce as much as possible the time-to-market.

A typical way to build large moulds is to prepare a pre-milled substructure with cheaper materials, to give sufficient stiffness to the mould.